Henry Ford may be remembered for putting the world on wheels, but his ongoing legacy to all motorists was how he did it: bringing the assembly line to car building. Without it, personal mobility would still be only for rich people.

That was a century ago, and as John Fleming, Ford’s executive vice-president for global manufacturing, observed, there aren’t many inventions in car building that are still operational 100 years later.

Henry got the idea from the armaments industry that, with war imminent, had to produce high volumes fast. It led to one of his famous philosophies: that no job is particularly hard when divided into small jobs.

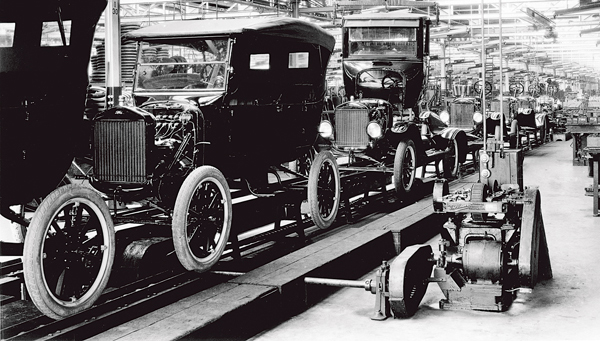

His first line was 46 metres long and dead straight. Each Model T chassis was pulled by a winch and a rope that was stretched along the factory floor, passing by 140 workers, who each added some of the 3000 parts it took to make the car. The line reduced the time taken to build each car from 12 hours to fewer than three.

Other processes had to be overhauled to keep up, especially delivery of parts. Overhead conveyors quickly arrived.

But assembly lines brought other fundamental changes to the industry. Henry quickly realised he no longer needed engineers to build cars and started employing workers with low skills who had no problem performing repeated tasks that quickly became rote. Absenteeism dropped, and when Henry started paying his workers $5 a day – enough to start them buying the cars they were building, it dropped again.

Today, the assembly line in Ford’s plant in Wayne, Michigan, is five kilometres long and employs 5000 workers across three shifts, complemented by 900 robots.

The added benefit is that each line can build a number of different cars, bringing significant cost reductions. But while the cars coming along the line may look totally different, they actually share many common parts; the differences are things the customer will see, the shared parts are mostly hidden under bodywork.

Henry never stopped tinkering with his assembly lines, and tinkering is now a constant in the industry; manufacturers are always trying new ways of getting lines running faster and cheaper. And they try to standardise them between countries. Toyota builds identical Camrys in eight different plants around the world.